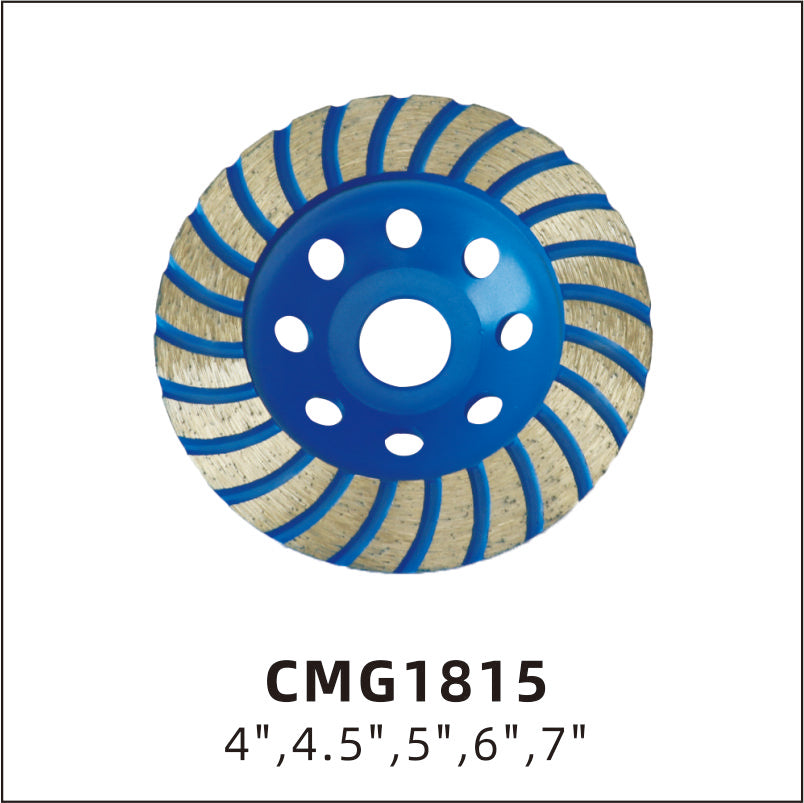

Diamond grinding wheel

-

Estimated Delivery:Feb 28 - Mar 04

-

Free Shipping & Returns: On all orders over $75

Diamond grinding wheel

CMG1815

Diamond grinding wheel is a heavy-duty grinding tool used for leveling. smoothing. and removing tough materials like concrete. stone. epoxy. and coatings. It consists of diamond segments bonded to a metal cup-shaped core. providing aggressive material removal with durability.

Key Features & Uses

✔ Material Removal: Ideal for grinding concrete. masonry. stone. and hard coatings.

✔ Segmented Design: Allows airflow for cooling. reducing heat buildup.

✔ Bond Types:

Metal Bond – Most durable. for hard concrete and stone.

Resin Bond – Smoother finish. for softer materials like epoxy.

Hybrid Bond – Balanced performance.

✔ Wet or Dry Use: Some require water cooling (wet grinding). while others are for dry use.

Types of Diamond Cup Wheels

Single Row Cup Wheel – Basic grinding. general-purpose concrete work.

Double/Triple Row Cup Wheel – More aggressive removal. longer lifespan.

Turbo Cup Wheel – Faster cutting with segmented rim. less vibration.

PCD (Polycrystalline Diamond) Cup Wheel – For ultra-hard surfaces like polished concrete.

Advantages Over Abrasive Wheels

Longer lifespan – Diamonds stay sharp much longer than abrasives.

Faster grinding – More efficient material removal.

Less vibration – Smoother operation than traditional grinding discs.

Choosing the Right Diamond Cup Wheel

For Concrete Grinding: Coarse grit (16-30). metal bond.

For Epoxy Removal: Medium grit (50-80). resin bond.

For Smooth Finishing: Fine grit (100+). hybrid or resin bond.

Wet vs. Dry: Wet grinding reduces dust but requires water; dry is more convenient.

Best Practices for Use

Wear PPE (respirator. goggles. gloves) – Silica dust is hazardous.

Check RPM Rating – Must match your grinder's speed.

Use Proper Pressure – Let the diamonds do the work; avoid forcing it.